Specialist Laser Cutting & Steel Suppliers, Fabricators and Welders in Christchurch, New Zealand

With over 67 years running experience, Priest Sheetmetal is an established name as a manufacturer and supplier of profile cut and fabricated steelwork to Christchurch businesses.

Our skilled team of tradesman, draftsman and general engineers offer a range of plate processing and metal fabrication services to meet your engineering needs. With the latest in CNC machinery, CAD software and one of the largest selections of steel folding press brakes in New Zealand we can be sure to assist you at every stage; from design, prototyping through to production.

Services

Adding value through craftsmanship.

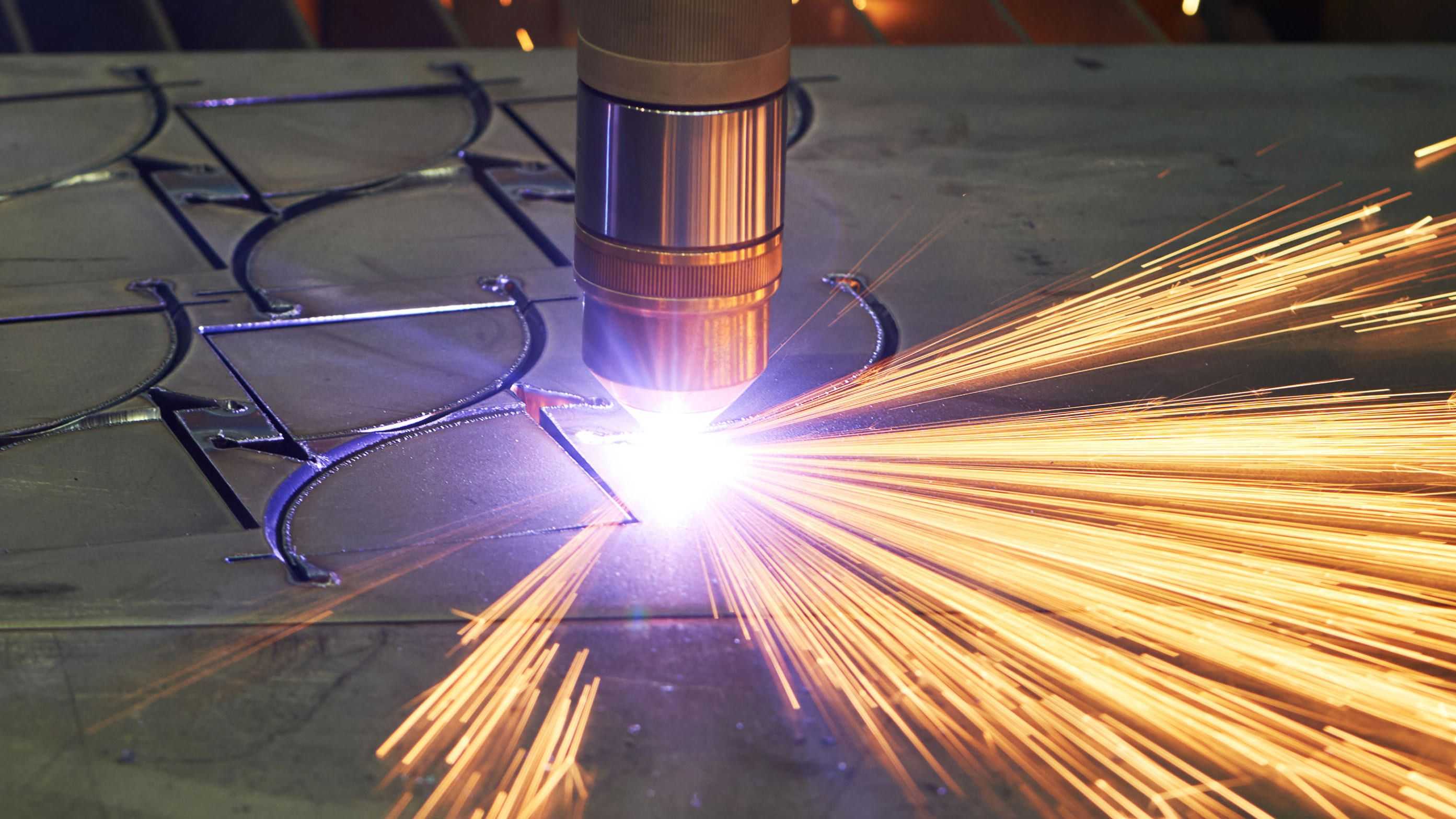

Laser Cutting & Profle Cutting

12kW Fibre South Islands Most Powerful Laser

Using the latest in Laser and Plasma CNC technology. We process heavy plate and precise laser cut sheetmetal parts to the South Island.

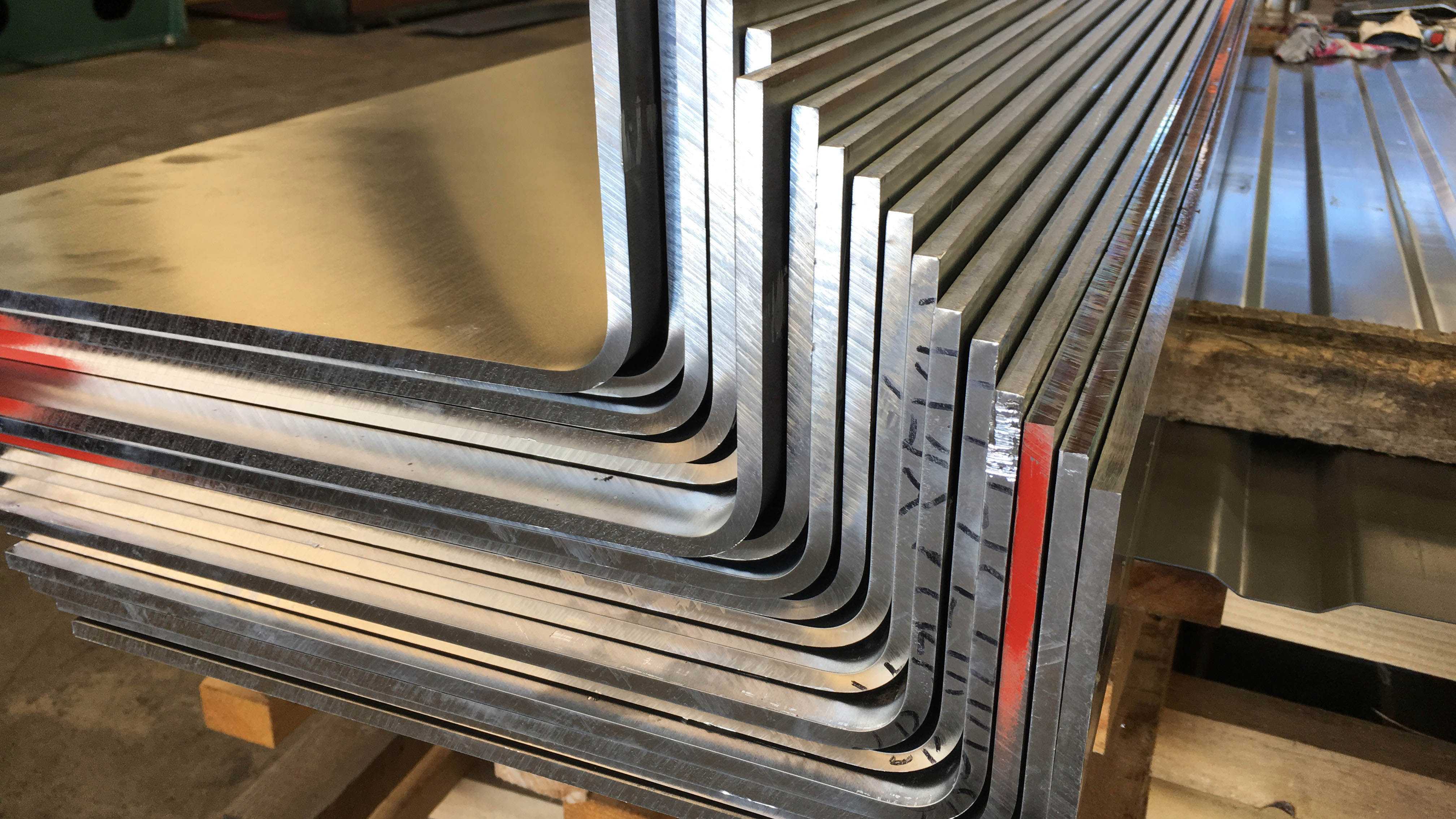

Press Brake Folding

Highly Accurate 7-axis 3D controllable metal pressing for quick and cost-effective folding of sheetmetal products. Large plate folding capacity for heavy plate and high tensile steels up to 5 metres in length. Our workshop is equipped with 6 hydraulic press brakes and a vast library of tooling for radius folding and difficult profiles.

Welding & Fabrication

Steel, Aluminum, Stainless, Brass, and Copper welding for commercial and private projects using a variety of welding machines and techniques, including TIG, MIG, Arc, and resistance spot welding in our full fabrication workshop. Precision jobs are done on our welding jig table – 3600mm x 1200mm, for efficient and accurate positioning of unique and large scale jobs.

Steel Supply and Plate Processing

We carry a comprehensive range of materials. Part sheets to commercial wholesale quantities

CAD Drawing & Design

If you have a new design, or you are recreating a product, our drawing office can create both 3D and 2D models for complex parts and assemblies.

Plate & Ring Rolling

Plate forming and rolling of SHS, RHS, Pipe, and Tubes up to 6mm x 2400mm in length. Precise rolling of flat bar or extrusions, rolling tubes and pipes, to form mark-free curves, flanges, and coils, without distortion.

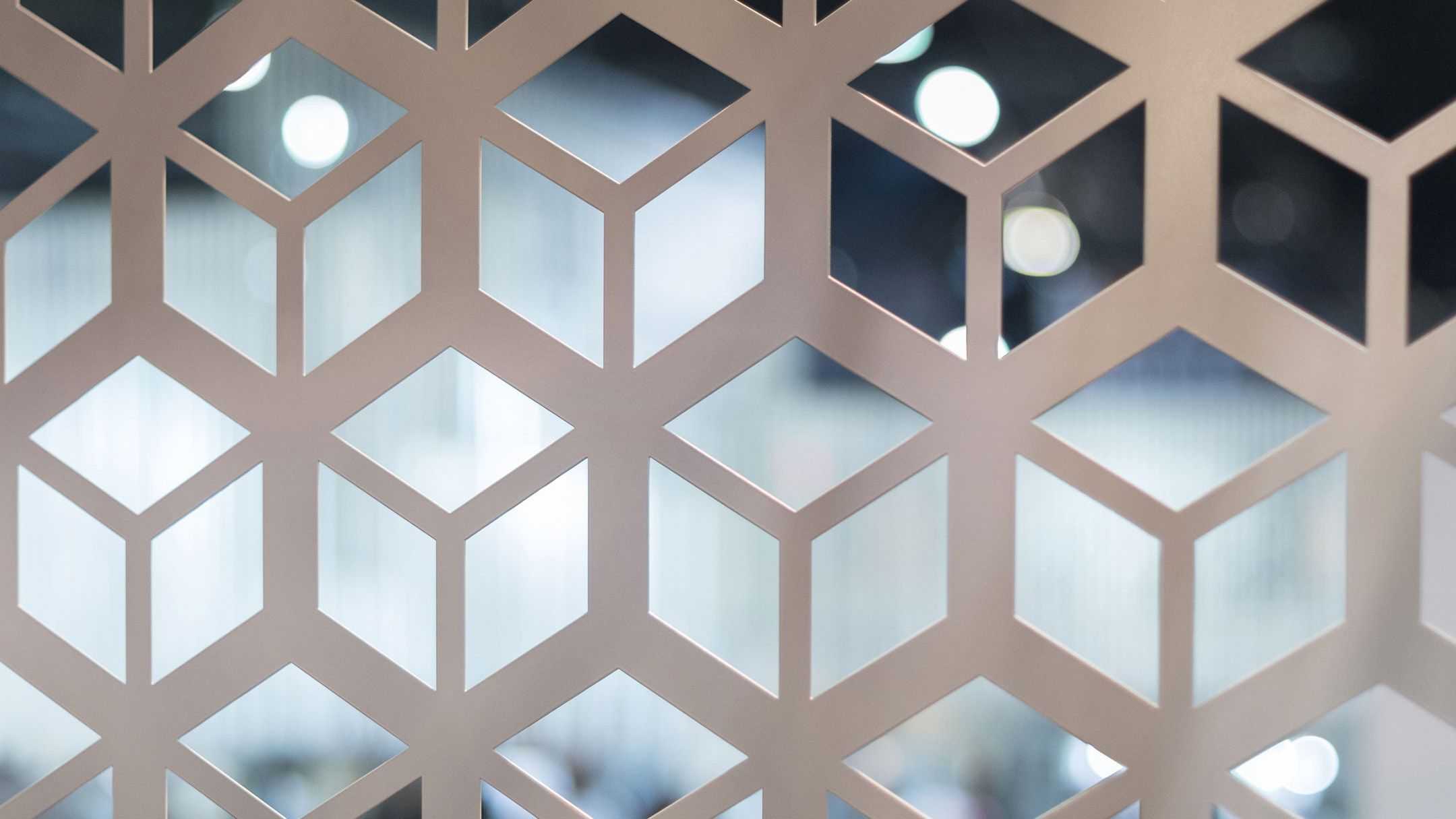

Turret Punching

Cost-effective metal punching up to 16mm plate. Able to punch slots, louvers, and holes to a standard aperture or perforate to an architectural design from our library or per your design specs. Turret punching is well suited to large production runs, is very precise, and is a lot quicker and cutting repetitive holes or shapes than laser cutting.

Materials

Thickness and Options

- 0.7

- 0.95

- 1.2

- 1.6

- 2

- 2.5

- 3

- 4

- 5

- 6

- 8

- 10

- 12

- 16

- 20

- 25

- 32

- 40

- 50

- 60

- 65

- 70

- 80

- 100

- 120

- carbon

- GR250

- ✓1.6

- ✓2

- ✓3

- ✓4

- ✓60

- ✓80

- ✓100

- ✓120

- GR300

- ✓5

- ✓6

- ✓8

- ✓10

- ✓12

- ✓16

- ✓20

- ✓25

- ✓32

- ✓40

- ✓50

- ✓60

- ✓65

- GR350

- ✓5

- ✓6

- ✓8

- ✓10

- ✓12

- ✓16

- ✓20

- ✓25

- ✓32

- ✓40

- ✓50

- ✓60

- ✓65

- ✓80

- ✓100

- CORTEN

- ✓1.6

- ✓2.5

- ✓3

- ✓4

- ✓5

- ✓6

- Boilerplate

- ✓6

- Bis 80 / HT

- ✓3

- ✓4

- ✓5

- ✓6

- ✓8

- ✓10

- ✓12

- ✓16

- ✓20

- ✓25

- ✓32

- ✓40

- ✓50

- ✓60

- ✓70

- Bis 400 / WP

- ✓4

- ✓5

- ✓6

- ✓8

- ✓10

- ✓12

- ✓16

- ✓20

- ✓25

- ✓32

- Electro Galv

- ✓0.7

- ✓0.95

- ✓1.2

- ✓1.6

- ✓2

- ✓2.5

- ✓3

- Hot Dipped Galv

- ✓0.7

- ✓0.95

- ✓1.2

- ✓1.6

- ✓2

- ✓2.5

- ✓3

- Tread Plate

- ✓3

- ✓5

- ✓6

- ✓8

- ✓10

- 0.7

- 0.95

- 1.2

- 1.6

- 2

- 2.5

- 3

- 4

- 5

- 6

- 8

- 10

- 12

- 16

- 20

- 25

- 32

- 40

- 50

- 60

- 65

- 70

- 80

- 100

- 120

- Stainless Steel

- 304 -L

- ✓0.7

- ✓0.95

- ✓1.2

- ✓1.6

- ✓2

- ✓2.5

- ✓3

- ✓4

- ✓5

- ✓6

- ✓8

- ✓10

- ✓12

- ✓16

- ✓20

- ✓25

- ✓32

- ✓40

- 316 -L

- ✓0.7

- ✓0.95

- ✓1.2

- ✓1.6

- ✓2

- ✓2.5

- ✓3

- ✓4

- ✓5

- ✓6

- ✓8

- ✓10

- ✓12

- ✓16

- ✓20

- ✓25

- ✓32

- ✓40

- Tread Plate

- ✓3

- ✓6

- 0.7

- 0.95

- 1.2

- 1.6

- 2

- 2.5

- 3

- 4

- 5

- 6

- 8

- 10

- 12

- 16

- 20

- 25

- 32

- 40

- 50

- 60

- 65

- 70

- 80

- 100

- 120

- Aluminium

- 5052

- ✓2

- ✓2.5

- ✓3

- ✓4

- ✓5

- ✓6

- 5083

- ✓4

- ✓5

- ✓6

- ✓8

- ✓10

- ✓12

- ✓16

- ✓20

- ✓25

- ✓40

- 5005

- ✓0.7

- ✓0.95

- ✓1.2

- ✓1.6

- ✓2

- ✓2.5

- ✓3

- ✓4

- ✓5

- ✓6